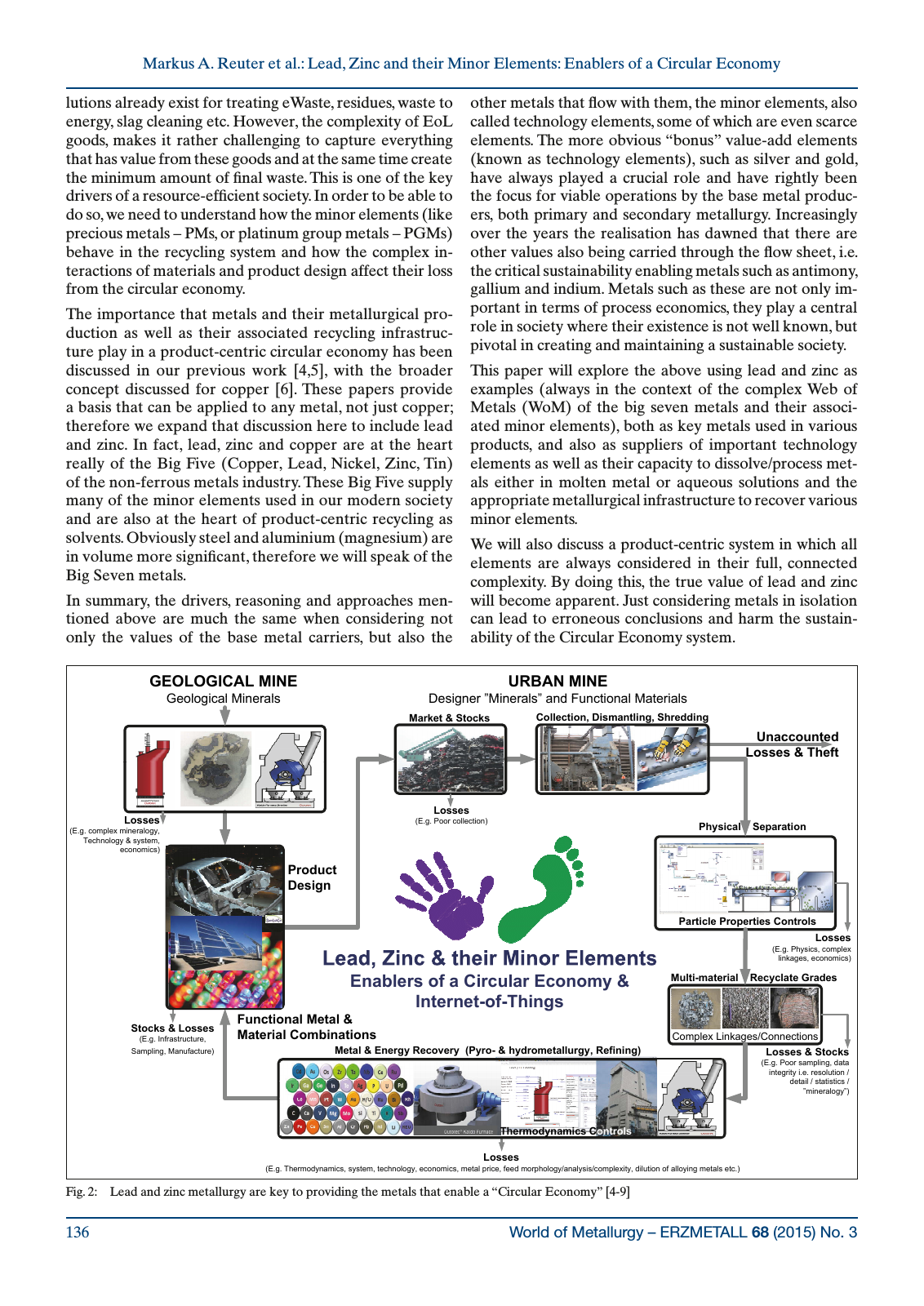

World of Metallurgy ERZMETALL 68 2015 No 3136 Markus A Reuter et al Lead Zinc and their Minor Elements Enablers of a Circular Economy lutions already exist for treating eWaste residues waste to energy slag cleaning etc However the complexity of EoL goods makes it rather challenging to capture everything that has value from these goods and at the same time create the minimum amount of final waste This is one of the key drivers of a resource efficient society In order to be able to do so we need to understand how the minor elements like precious metals PMs or platinum group metals PGMs behave in the recycling system and how the complex in teractions of materials and product design affect their loss from the circular economy The importance that metals and their metallurgical pro duction as well as their associated recycling infrastruc ture play in a product centric circular economy has been discussed in our previous work 4 5 with the broader concept discussed for copper 6 These papers provide a basis that can be applied to any metal not just copper therefore we expand that discussion here to include lead and zinc In fact lead zinc and copper are at the heart really of the Big Five Copper Lead Nickel Zinc Tin of the non ferrous metals industry These Big Five supply many of the minor elements used in our modern society and are also at the heart of product centric recycling as solvents Obviously steel and aluminium magnesium are in volume more significant therefore we will speak of the Big Seven metals In summary the drivers reasoning and approaches men tioned above are much the same when considering not only the values of the base metal carriers but also the other metals that flow with them the minor elements also called technology elements some of which are even scarce elements The more obvious bonus value add elements known as technology elements such as silver and gold have always played a crucial role and have rightly been the focus for viable operations by the base metal produc ers both primary and secondary metallurgy Increasingly over the years the realisation has dawned that there are other values also being carried through the flow sheet i e the critical sustainability enabling metals such as antimony gallium and indium Metals such as these are not only im portant in terms of process economics they play a central role in society where their existence is not well known but pivotal in creating and maintaining a sustainable society This paper will explore the above using lead and zinc as examples always in the context of the complex Web of Metals WoM of the big seven metals and their associ ated minor elements both as key metals used in various products and also as suppliers of important technology elements as well as their capacity to dissolve process met als either in molten metal or aqueous solutions and the appropriate metallurgical infrastructure to recover various minor elements We will also discuss a product centric system in which all elements are always considered in their full connected complexity By doing this the true value of lead and zinc will become apparent Just considering metals in isolation can lead to erroneous conclusions and harm the sustain ability of the Circular Economy system Fig 2 Lead and zinc metallurgy are key to providing the metals that enable a Circular Economy 4 9 Figure 2 Reuter URBAN MINE Designer Minerals and Functional Materials GEOLOGICAL MINE Geological Minerals Collection Dismantling Shredding Unaccounted Losses Theft Market Stocks Physical Separation Losses Losses E g Poor collection Product Design E g complex mineralogy Technology system economics Losses E g Physics complex linkages economics Particle Properties Controls Functional Metal Multi material Recyclate Grades Enablers of a Circular Economy Internet of Things Material Combinations Metal Energy Recovery Pyro hydrometallurgy Refining Losses Stocks E g Poor sampling data integrity i e resolution detail statistics i l Complex Linkages Connections Stocks Losses E g Infrastructure Sampling Manufacture L m nera ogy c MARThermodynamics Controls osses E g Thermodynamics system technology economics metal price feed morphology analysis complexity dilution of alloying metals etc

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.