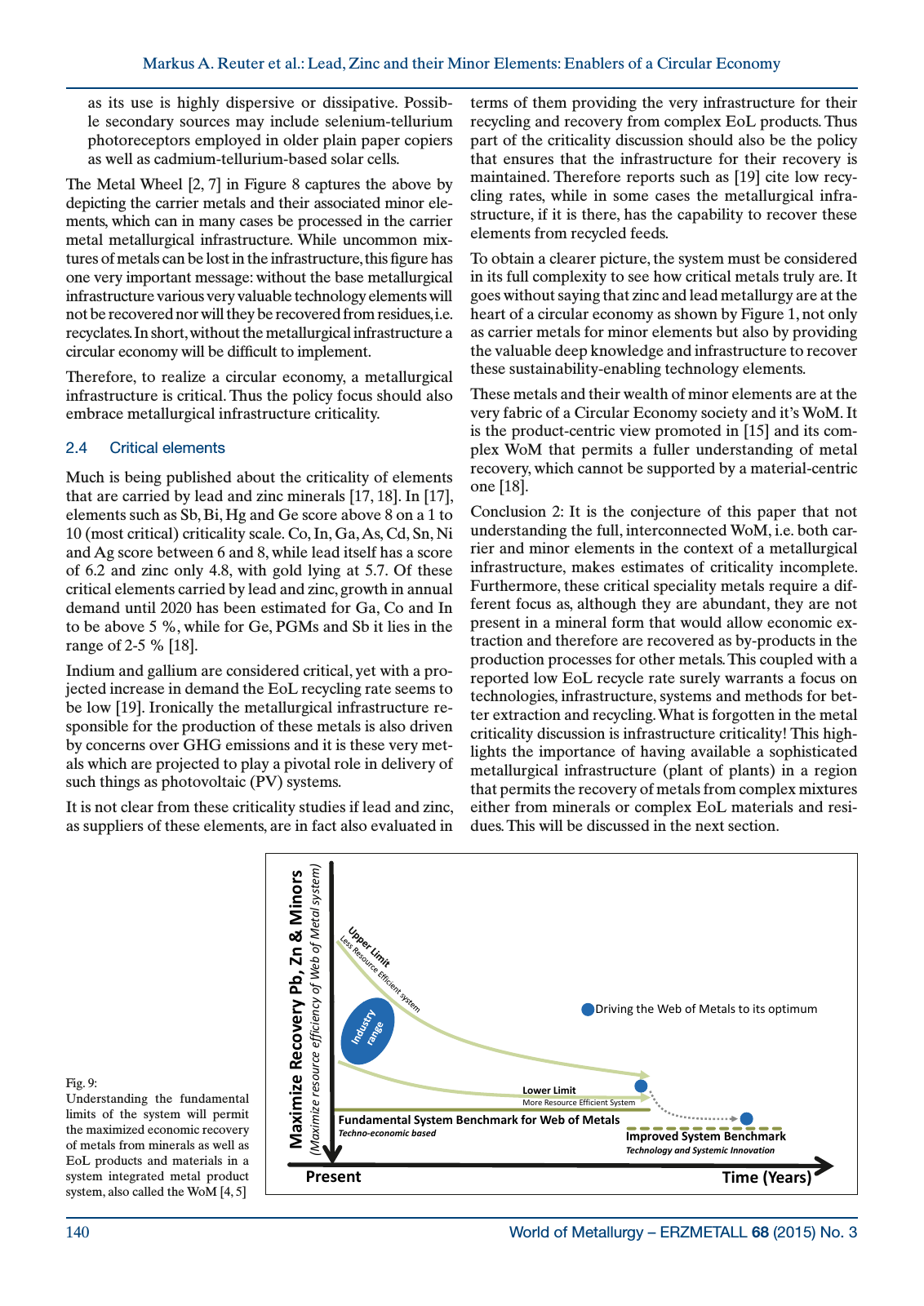

World of Metallurgy ERZMETALL 68 2015 No 3140 Markus A Reuter et al Lead Zinc and their Minor Elements Enablers of a Circular Economy as its use is highly dispersive or dissipative Possib le secondary sources may include selenium tellurium photoreceptors employed in older plain paper copiers as well as cadmium tellurium based solar cells The Metal Wheel 2 7 in Figure 8 captures the above by depicting the carrier metals and their associated minor ele ments which can in many cases be processed in the carrier metal metallurgical infrastructure While uncommon mix tures of metals can be lost in the infrastructure this figure has one very important message without the base metallurgical infrastructure various very valuable technology elements will not be recovered nor will they be recovered from residues i e recyclates In short without the metallurgical infrastructure a circular economy will be difficult to implement Therefore to realize a circular economy a metallurgical infrastructure is critical Thus the policy focus should also embrace metallurgical infrastructure criticality 2 4 Critical elements Much is being published about the criticality of elements that are carried by lead and zinc minerals 17 18 In 17 elements such as Sb Bi Hg and Ge score above 8 on a 1 to 10 most critical criticality scale Co In Ga As Cd Sn Ni and Ag score between 6 and 8 while lead itself has a score of 6 2 and zinc only 4 8 with gold lying at 5 7 Of these critical elements carried by lead and zinc growth in annual demand until 2020 has been estimated for Ga Co and In to be above 5 while for Ge PGMs and Sb it lies in the range of 2 5 18 Indium and gallium are considered critical yet with a pro jected increase in demand the EoL recycling rate seems to be low 19 Ironically the metallurgical infrastructure re sponsible for the production of these metals is also driven by concerns over GHG emissions and it is these very met als which are projected to play a pivotal role in delivery of such things as photovoltaic PV systems It is not clear from these criticality studies if lead and zinc as suppliers of these elements are in fact also evaluated in terms of them providing the very infrastructure for their recycling and recovery from complex EoL products Thus part of the criticality discussion should also be the policy that ensures that the infrastructure for their recovery is maintained Therefore reports such as 19 cite low recy cling rates while in some cases the metallurgical infra structure if it is there has the capability to recover these elements from recycled feeds To obtain a clearer picture the system must be considered in its full complexity to see how critical metals truly are It goes without saying that zinc and lead metallurgy are at the heart of a circular economy as shown by Figure 1 not only as carrier metals for minor elements but also by providing the valuable deep knowledge and infrastructure to recover these sustainability enabling technology elements These metals and their wealth of minor elements are at the very fabric of a Circular Economy society and it s WoM It is the product centric view promoted in 15 and its com plex WoM that permits a fuller understanding of metal recovery which cannot be supported by a material centric one 18 Conclusion 2 It is the conjecture of this paper that not understanding the full interconnected WoM i e both car rier and minor elements in the context of a metallurgical infrastructure makes estimates of criticality incomplete Furthermore these critical speciality metals require a dif ferent focus as although they are abundant they are not present in a mineral form that would allow economic ex traction and therefore are recovered as by products in the production processes for other metals This coupled with a reported low EoL recycle rate surely warrants a focus on technologies infrastructure systems and methods for bet ter extraction and recycling What is forgotten in the metal criticality discussion is infrastructure criticality This high lights the importance of having available a sophisticated metallurgical infrastructure plant of plants in a region that permits the recovery of metals from complex mixtures either from minerals or complex EoL materials and resi dues This will be discussed in the next section Fig 9 Understanding the fundamental limits of the system will permit the maximized economic recovery of metals from minerals as well as EoL products and materials in a system integrated metal product system also called the WoM 4 5 Figure 9 Reuter ino rs l sy ste m n M of Me tal y P b Zn y o f W eb co ve ry eff icie nc y Driving the Web of Metals to its optimum ize Re c res ou rce Lower Limit Fundamental System Benchmark for Web of Metals Techno economic basedMa xim i Ma xim ize r Improved System Benchmark More Resource Efficient System M M Present Time Years Technology and Systemic Innovation

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.