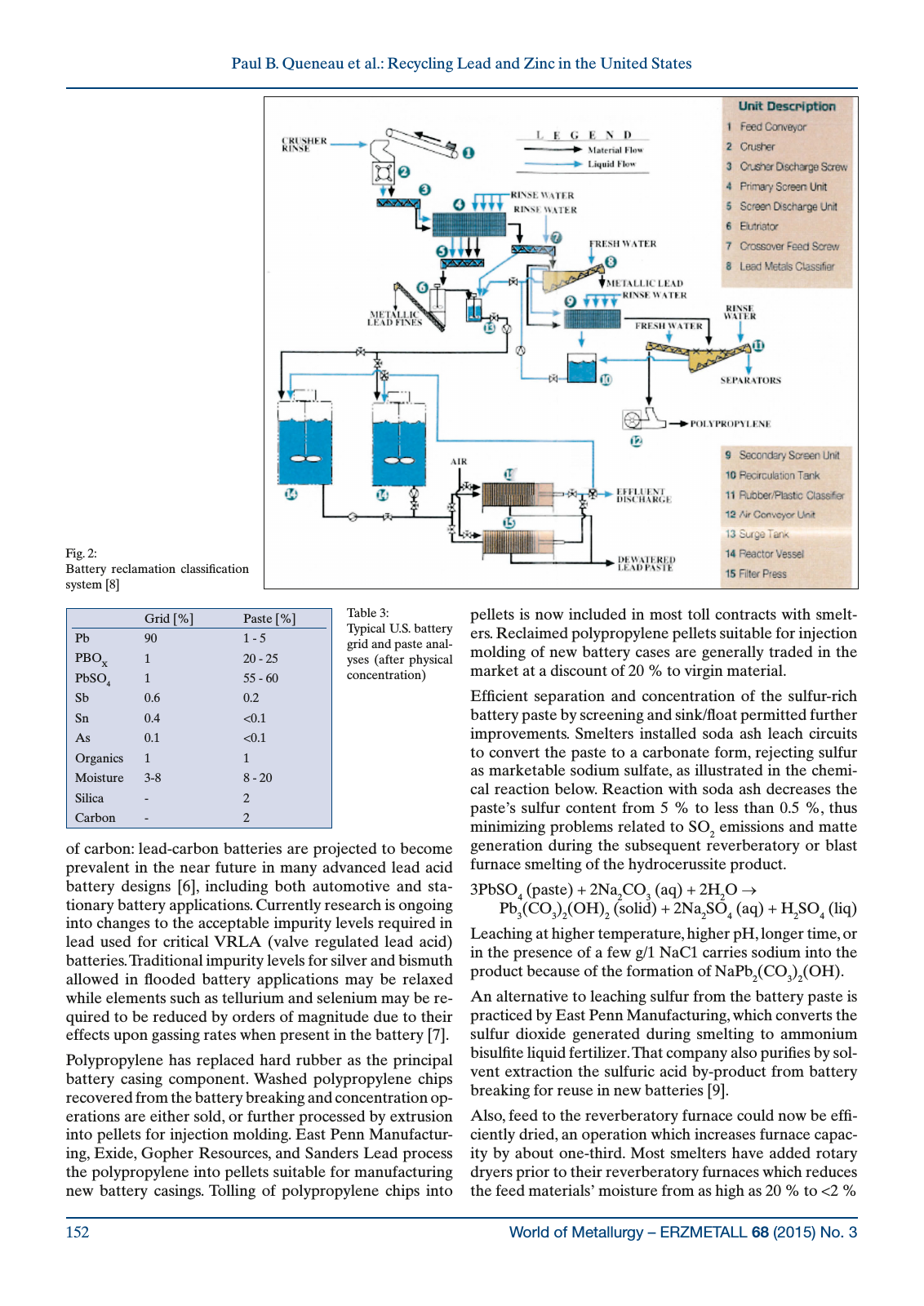

World of Metallurgy ERZMETALL 68 2015 No 3152 Paul B Queneau et al Recycling Lead and Zinc in the United States of carbon lead carbon batteries are projected to become prevalent in the near future in many advanced lead acid battery designs 6 including both automotive and sta tionary battery applications Currently research is ongoing into changes to the acceptable impurity levels required in lead used for critical VRLA valve regulated lead acid batteries Traditional impurity levels for silver and bismuth allowed in flooded battery applications may be relaxed while elements such as tellurium and selenium may be re quired to be reduced by orders of magnitude due to their effects upon gassing rates when present in the battery 7 Polypropylene has replaced hard rubber as the principal battery casing component Washed polypropylene chips recovered from the battery breaking and concentration op erations are either sold or further processed by extrusion into pellets for injection molding East Penn Manufactur ing Exide Gopher Resources and Sanders Lead process the polypropylene into pellets suitable for manufacturing new battery casings Tolling of polypropylene chips into pellets is now included in most toll contracts with smelt ers Reclaimed polypropylene pellets suitable for injection molding of new battery cases are generally traded in the market at a discount of 20 to virgin material Efficient separation and concentration of the sulfur rich battery paste by screening and sink float permitted further improvements Smelters installed soda ash leach circuits to convert the paste to a carbonate form rejecting sulfur as marketable sodium sulfate as illustrated in the chemi cal reaction below Reaction with soda ash decreases the paste s sulfur content from 5 to less than 0 5 thus minimizing problems related to SO2 emissions and matte generation during the subsequent reverberatory or blast furnace smelting of the hydrocerussite product 3PbSO4 paste 2Na2CO3 aq 2H2O Pb3 CO3 2 OH 2 solid 2Na2SO4 aq H2SO4 liq Leaching at higher temperature higher pH longer time or in the presence of a few g 1 NaC1 carries sodium into the product because of the formation of NaPb2 CO3 2 OH An alternative to leaching sulfur from the battery paste is practiced by East Penn Manufacturing which converts the sulfur dioxide generated during smelting to ammonium bisulfite liquid fertilizer That company also purifies by sol vent extraction the sulfuric acid by product from battery breaking for reuse in new batteries 9 Also feed to the reverberatory furnace could now be effi ciently dried an operation which increases furnace capac ity by about one third Most smelters have added rotary dryers prior to their reverberatory furnaces which reduces the feed materials moisture from as high as 20 to 2 Grid Paste Pb 90 1 5 PBOX 1 20 25 PbSO4 1 55 60 Sb 0 6 0 2 Sn 0 4 0 1 As 0 1 0 1 Organics 1 1 Moisture 3 8 8 20 Silica 2 Carbon 2 Table 3 Typical U S battery grid and paste anal yses after physical concentration Fig 2 Battery reclamation classification system 8

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.