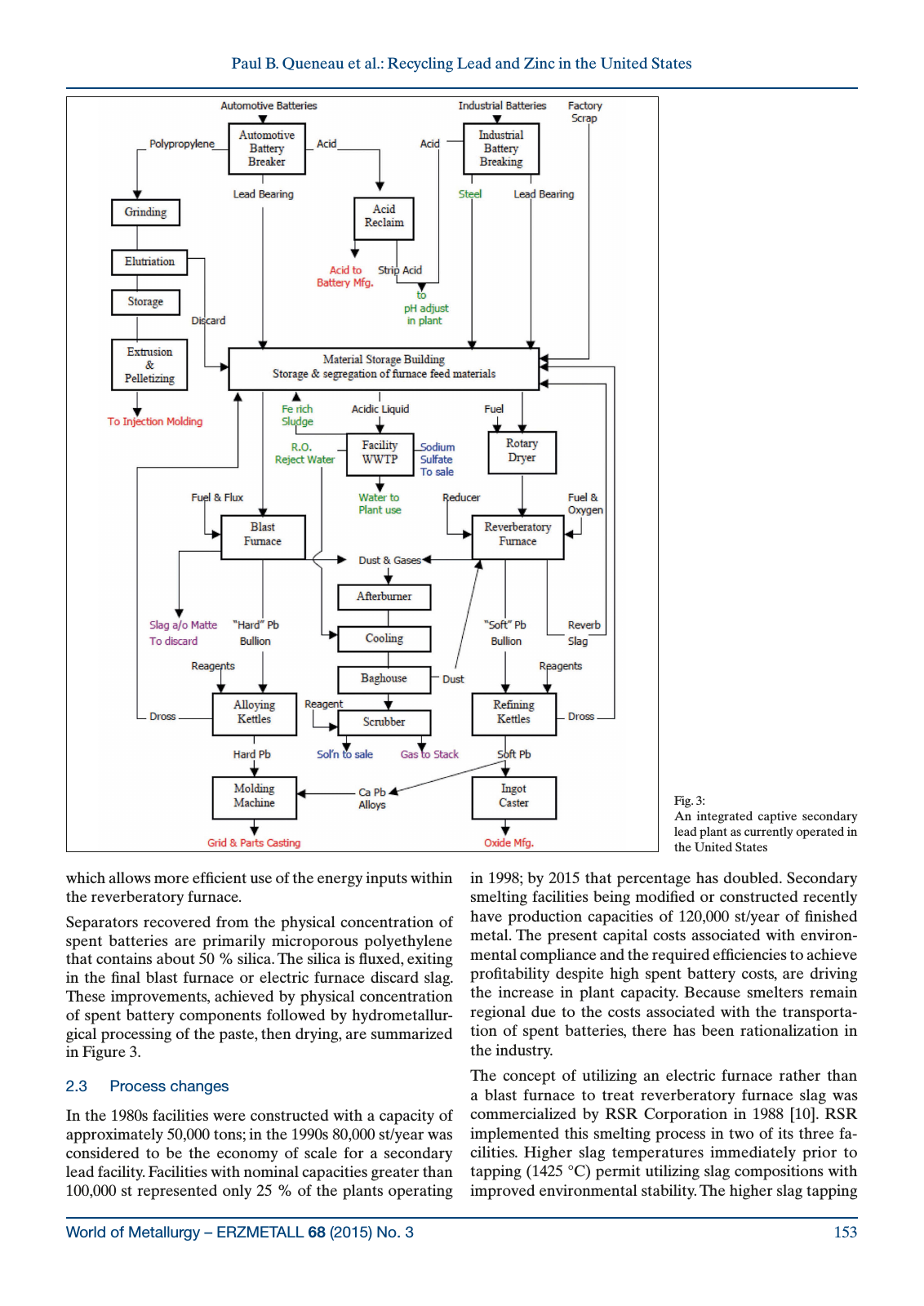

World of Metallurgy ERZMETALL 68 2015 No 3 153 Paul B Queneau et al Recycling Lead and Zinc in the United States which allows more efficient use of the energy inputs within the reverberatory furnace Separators recovered from the physical concentration of spent batteries are primarily microporous polyethylene that contains about 50 silica The silica is fluxed exiting in the final blast furnace or electric furnace discard slag These improvements achieved by physical concentration of spent battery components followed by hydrometallur gical processing of the paste then drying are summarized in Figure 3 2 3 Process changes In the 1980s facilities were constructed with a capacity of approximately 50 000 tons in the 1990s 80 000 st year was considered to be the economy of scale for a secondary lead facility Facilities with nominal capacities greater than 100 000 st represented only 25 of the plants operating in 1998 by 2015 that percentage has doubled Secondary smelting facilities being modified or constructed recently have production capacities of 120 000 st year of finished metal The present capital costs associated with environ mental compliance and the required efficiencies to achieve profitability despite high spent battery costs are driving the increase in plant capacity Because smelters remain regional due to the costs associated with the transporta tion of spent batteries there has been rationalization in the industry The concept of utilizing an electric furnace rather than a blast furnace to treat reverberatory furnace slag was commercialized by RSR Corporation in 1988 10 RSR implemented this smelting process in two of its three fa cilities Higher slag temperatures immediately prior to tapping 1425 C permit utilizing slag compositions with improved environmental stability The higher slag tapping Fig 3 An integrated captive secondary lead plant as currently operated in the United States

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.