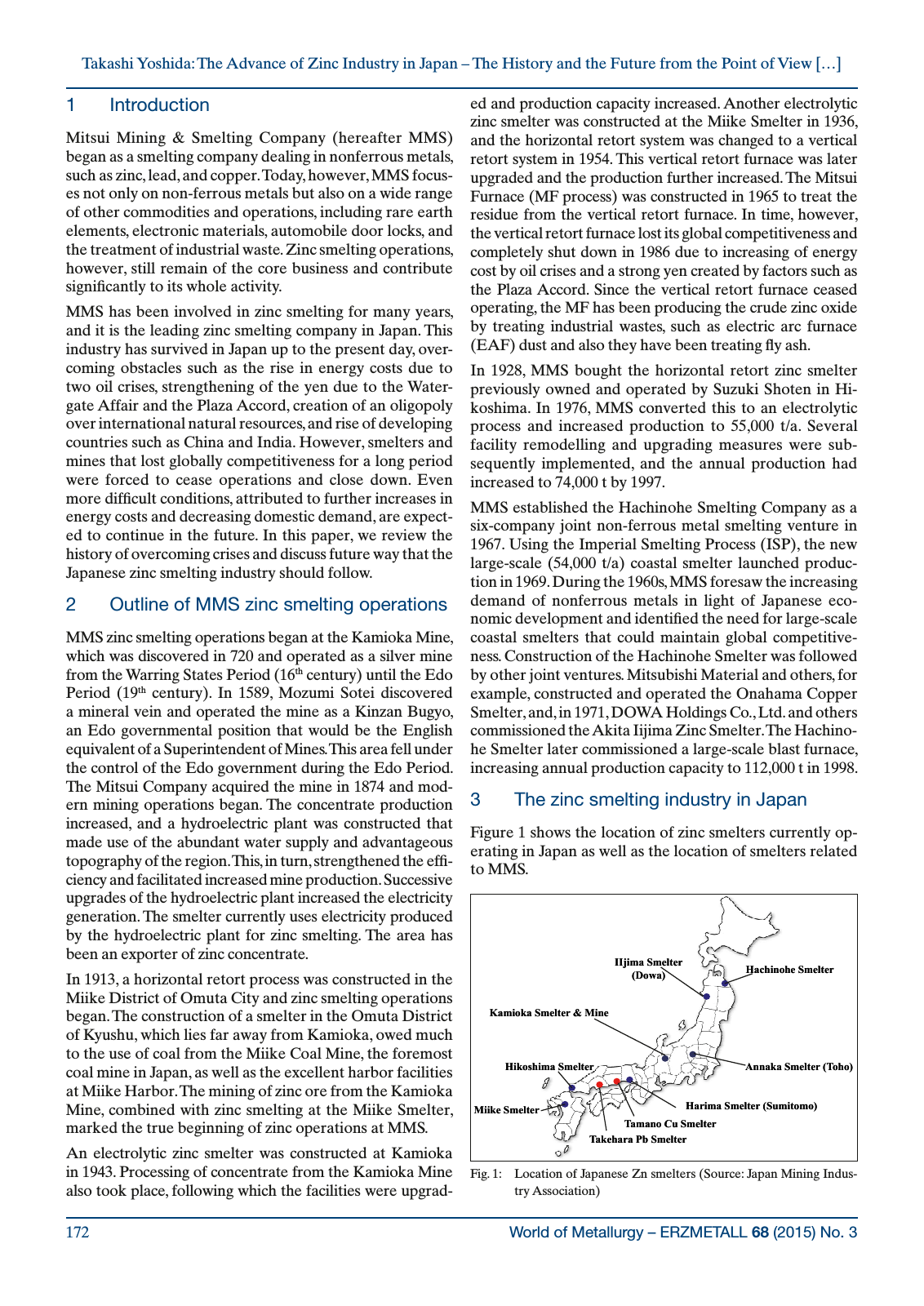

World of Metallurgy ERZMETALL 68 2015 No 3172 Takashi Yoshida The Advance of Zinc Industry in Japan The History and the Future from the Point of View 1 Introduction Mitsui Mining Smelting Company hereafter MMS began as a smelting company dealing in nonferrous metals such as zinc lead and copper Today however MMS focus es not only on non ferrous metals but also on a wide range of other commodities and operations including rare earth elements electronic materials automobile door locks and the treatment of industrial waste Zinc smelting operations however still remain of the core business and contribute significantly to its whole activity MMS has been involved in zinc smelting for many years and it is the leading zinc smelting company in Japan This industry has survived in Japan up to the present day over coming obstacles such as the rise in energy costs due to two oil crises strengthening of the yen due to the Water gate Affair and the Plaza Accord creation of an oligopoly over international natural resources and rise of developing countries such as China and India However smelters and mines that lost globally competitiveness for a long period were forced to cease operations and close down Even more difficult conditions attributed to further increases in energy costs and decreasing domestic demand are expect ed to continue in the future In this paper we review the history of overcoming crises and discuss future way that the Japanese zinc smelting industry should follow 2 Outline of MMS zinc smelting operations MMS zinc smelting operations began at the Kamioka Mine which was discovered in 720 and operated as a silver mine from the Warring States Period 16th century until the Edo Period 19th century In 1589 Mozumi Sotei discovered a mineral vein and operated the mine as a Kinzan Bugyo an Edo governmental position that would be the English equivalent of a Superintendent of Mines This area fell under the control of the Edo government during the Edo Period The Mitsui Company acquired the mine in 1874 and mod ern mining operations began The concentrate production increased and a hydroelectric plant was constructed that made use of the abundant water supply and advantageous topography of the region This in turn strengthened the effi ciency and facilitated increased mine production Successive upgrades of the hydroelectric plant increased the electricity generation The smelter currently uses electricity produced by the hydroelectric plant for zinc smelting The area has been an exporter of zinc concentrate In 1913 a horizontal retort process was constructed in the Miike District of Omuta City and zinc smelting operations began The construction of a smelter in the Omuta District of Kyushu which lies far away from Kamioka owed much to the use of coal from the Miike Coal Mine the foremost coal mine in Japan as well as the excellent harbor facilities at Miike Harbor The mining of zinc ore from the Kamioka Mine combined with zinc smelting at the Miike Smelter marked the true beginning of zinc operations at MMS An electrolytic zinc smelter was constructed at Kamioka in 1943 Processing of concentrate from the Kamioka Mine also took place following which the facilities were upgrad ed and production capacity increased Another electrolytic zinc smelter was constructed at the Miike Smelter in 1936 and the horizontal retort system was changed to a vertical retort system in 1954 This vertical retort furnace was later upgraded and the production further increased The Mitsui Furnace MF process was constructed in 1965 to treat the residue from the vertical retort furnace In time however the vertical retort furnace lost its global competitiveness and completely shut down in 1986 due to increasing of energy cost by oil crises and a strong yen created by factors such as the Plaza Accord Since the vertical retort furnace ceased operating the MF has been producing the crude zinc oxide by treating industrial wastes such as electric arc furnace EAF dust and also they have been treating fly ash In 1928 MMS bought the horizontal retort zinc smelter previously owned and operated by Suzuki Shoten in Hi koshima In 1976 MMS converted this to an electrolytic process and increased production to 55 000 t a Several facility remodelling and upgrading measures were sub sequently implemented and the annual production had increased to 74 000 t by 1997 MMS established the Hachinohe Smelting Company as a six company joint non ferrous metal smelting venture in 1967 Using the Imperial Smelting Process ISP the new large scale 54 000 t a coastal smelter launched produc tion in 1969 During the 1960s MMS foresaw the increasing demand of nonferrous metals in light of Japanese eco nomic development and identified the need for large scale coastal smelters that could maintain global competitive ness Construction of the Hachinohe Smelter was followed by other joint ventures Mitsubishi Material and others for example constructed and operated the Onahama Copper Smelter and in 1971 DOWA Holdings Co Ltd and others commissioned the Akita Iijima Zinc Smelter The Hachino he Smelter later commissioned a large scale blast furnace increasing annual production capacity to 112 000 t in 1998 3 The zinc smelting industry in Japan Figure 1 shows the location of zinc smelters currently op erating in Japan as well as the location of smelters related to MMS Fig 1 Location of Japanese Zn smelters Source Japan Mining Indus try Association Hachinohe SmelterIIjima Smelter Dowa Kamioka Smelter Mine Hikoshima Smelter Annaka Smelter Toho Miike Smelter Tamano Cu Smelter Harima Smelter Sumitomo Takehara Pb Smelter

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.