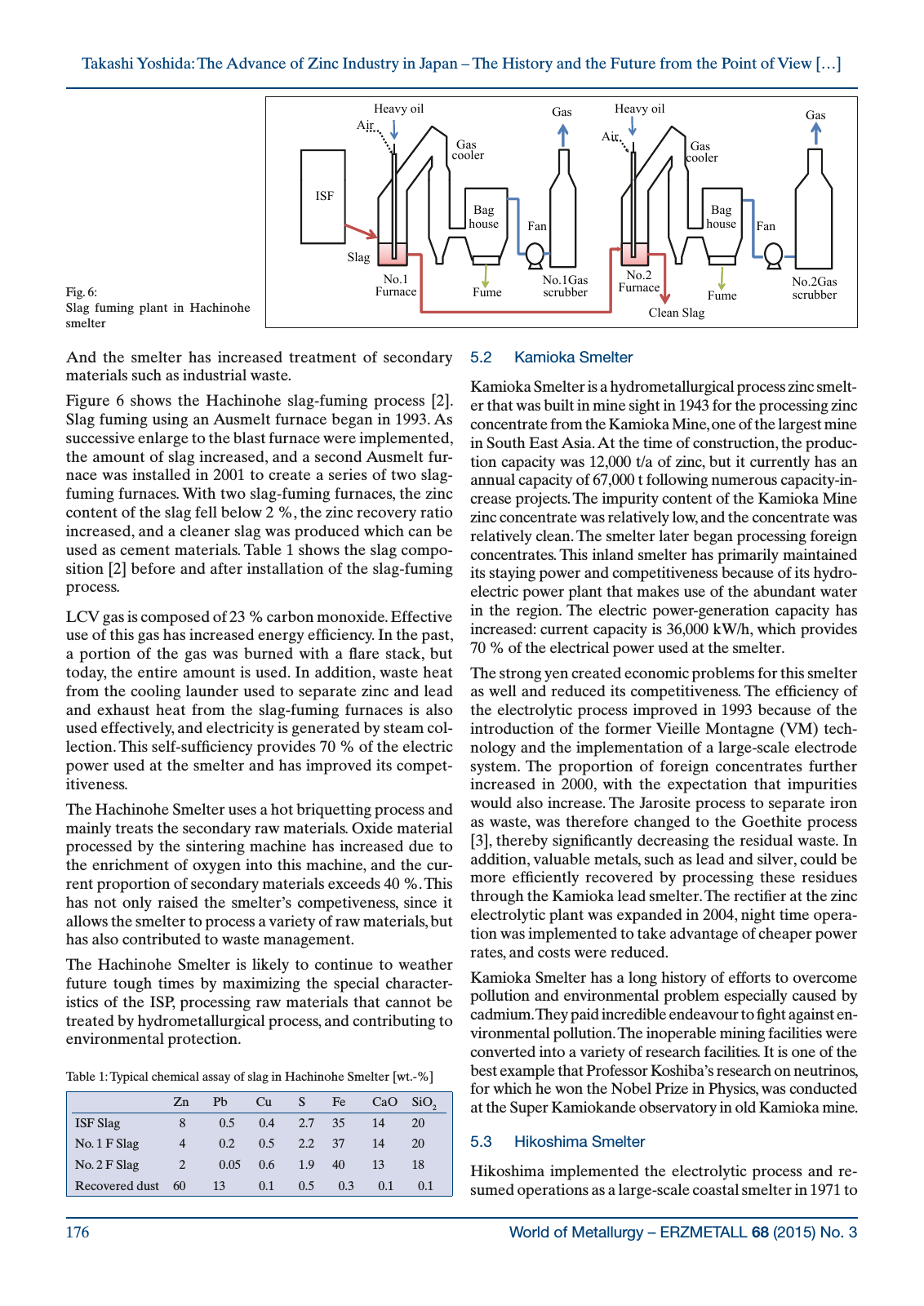

World of Metallurgy ERZMETALL 68 2015 No 3176 Takashi Yoshida The Advance of Zinc Industry in Japan The History and the Future from the Point of View And the smelter has increased treatment of secondary materials such as industrial waste Figure 6 shows the Hachinohe slag fuming process 2 Slag fuming using an Ausmelt furnace began in 1993 As successive enlarge to the blast furnace were implemented the amount of slag increased and a second Ausmelt fur nace was installed in 2001 to create a series of two slag fuming furnaces With two slag fuming furnaces the zinc content of the slag fell below 2 the zinc recovery ratio increased and a cleaner slag was produced which can be used as cement materials Table 1 shows the slag compo sition 2 before and after installation of the slag fuming process LCV gas is composed of 23 carbon monoxide Effective use of this gas has increased energy efficiency In the past a portion of the gas was burned with a flare stack but today the entire amount is used In addition waste heat from the cooling launder used to separate zinc and lead and exhaust heat from the slag fuming furnaces is also used effectively and electricity is generated by steam col lection This self sufficiency provides 70 of the electric power used at the smelter and has improved its compet itiveness The Hachinohe Smelter uses a hot briquetting process and mainly treats the secondary raw materials Oxide material processed by the sintering machine has increased due to the enrichment of oxygen into this machine and the cur rent proportion of secondary materials exceeds 40 This has not only raised the smelter s competiveness since it allows the smelter to process a variety of raw materials but has also contributed to waste management The Hachinohe Smelter is likely to continue to weather future tough times by maximizing the special character istics of the ISP processing raw materials that cannot be treated by hydrometallurgical process and contributing to environmental protection 5 2 Kamioka Smelter Kamioka Smelter is a hydrometallurgical process zinc smelt er that was built in mine sight in 1943 for the processing zinc concentrate from the Kamioka Mine one of the largest mine in South East Asia At the time of construction the produc tion capacity was 12 000 t a of zinc but it currently has an annual capacity of 67 000 t following numerous capacity in crease projects The impurity content of the Kamioka Mine zinc concentrate was relatively low and the concentrate was relatively clean The smelter later began processing foreign concentrates This inland smelter has primarily maintained its staying power and competitiveness because of its hydro electric power plant that makes use of the abundant water in the region The electric power generation capacity has increased current capacity is 36 000 kW h which provides 70 of the electrical power used at the smelter The strong yen created economic problems for this smelter as well and reduced its competitiveness The efficiency of the electrolytic process improved in 1993 because of the introduction of the former Vieille Montagne VM tech nology and the implementation of a large scale electrode system The proportion of foreign concentrates further increased in 2000 with the expectation that impurities would also increase The Jarosite process to separate iron as waste was therefore changed to the Goethite process 3 thereby significantly decreasing the residual waste In addition valuable metals such as lead and silver could be more efficiently recovered by processing these residues through the Kamioka lead smelter The rectifier at the zinc electrolytic plant was expanded in 2004 night time opera tion was implemented to take advantage of cheaper power rates and costs were reduced Kamioka Smelter has a long history of efforts to overcome pollution and environmental problem especially caused by cadmium They paid incredible endeavour to fight against en vironmental pollution The inoperable mining facilities were converted into a variety of research facilities It is one of the best example that Professor Koshiba s research on neutrinos for which he won the Nobel Prize in Physics was conducted at the Super Kamiokande observatory in old Kamioka mine 5 3 Hikoshima Smelter Hikoshima implemented the electrolytic process and re sumed operations as a large scale coastal smelter in 1971 to Fig 6 Slag fuming plant in Hachinohe smelter Air Heavy oil Heavy oilGas Gas Air Gas cooler Gas cooler ISF Fan Fan Bag house Bag house Slag No 1 F No 2 FurnaceF No 1Gas bb No 2Gas urnace Clean Slag ume Fumescru er scrubber Table 1 Typical chemical assay of slag in Hachinohe Smelter wt Zn Pb Cu S Fe CaO SiO2 ISF Slag 8 0 5 0 4 2 7 35 14 20 No 1 F Slag 4 0 2 0 5 2 2 37 14 20 No 2 F Slag 2 0 05 0 6 1 9 40 13 18 Recovered dust 60 13 0 1 0 5 0 3 0 1 0 1

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.