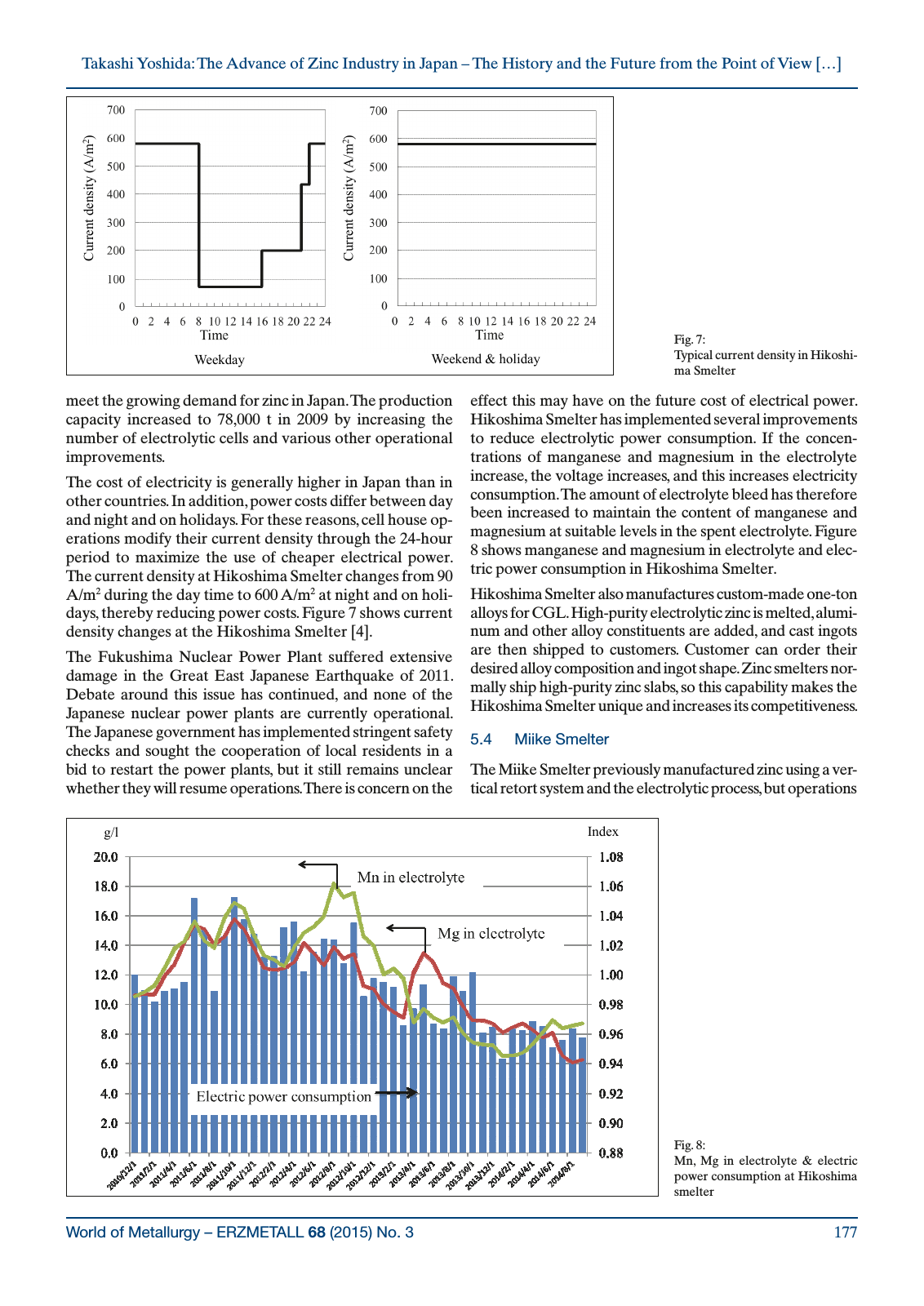

World of Metallurgy ERZMETALL 68 2015 No 3 177 Takashi Yoshida The Advance of Zinc Industry in Japan The History and the Future from the Point of View meet the growing demand for zinc in Japan The production capacity increased to 78 000 t in 2009 by increasing the number of electrolytic cells and various other operational improvements The cost of electricity is generally higher in Japan than in other countries In addition power costs differ between day and night and on holidays For these reasons cell house op erations modify their current density through the 24 hour period to maximize the use of cheaper electrical power The current density at Hikoshima Smelter changes from 90 A m2 during the day time to 600 A m2 at night and on holi days thereby reducing power costs Figure 7 shows current density changes at the Hikoshima Smelter 4 The Fukushima Nuclear Power Plant suffered extensive damage in the Great East Japanese Earthquake of 2011 Debate around this issue has continued and none of the Japanese nuclear power plants are currently operational The Japanese government has implemented stringent safety checks and sought the cooperation of local residents in a bid to restart the power plants but it still remains unclear whether they will resume operations There is concern on the effect this may have on the future cost of electrical power Hikoshima Smelter has implemented several improvements to reduce electrolytic power consumption If the concen trations of manganese and magnesium in the electrolyte increase the voltage increases and this increases electricity consumption The amount of electrolyte bleed has therefore been increased to maintain the content of manganese and magnesium at suitable levels in the spent electrolyte Figure 8 shows manganese and magnesium in electrolyte and elec tric power consumption in Hikoshima Smelter Hikoshima Smelter also manufactures custom made one ton alloys for CGL High purity electrolytic zinc is melted alumi num and other alloy constituents are added and cast ingots are then shipped to customers Customer can order their desired alloy composition and ingot shape Zinc smelters nor mally ship high purity zinc slabs so this capability makes the Hikoshima Smelter unique and increases its competitiveness 5 4 Miike Smelter The Miike Smelter previously manufactured zinc using a ver tical retort system and the electrolytic process but operations Fig 7 Typical current density in Hikoshi ma Smelter ity A m 2 ity A m 2 rre nt d en s i rre nt d en s i Cu r Cu r Weekday Weekend holiday Fig 8 Mn Mg in electrolyte electric power consumption at Hikoshima smelter g l Index

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.