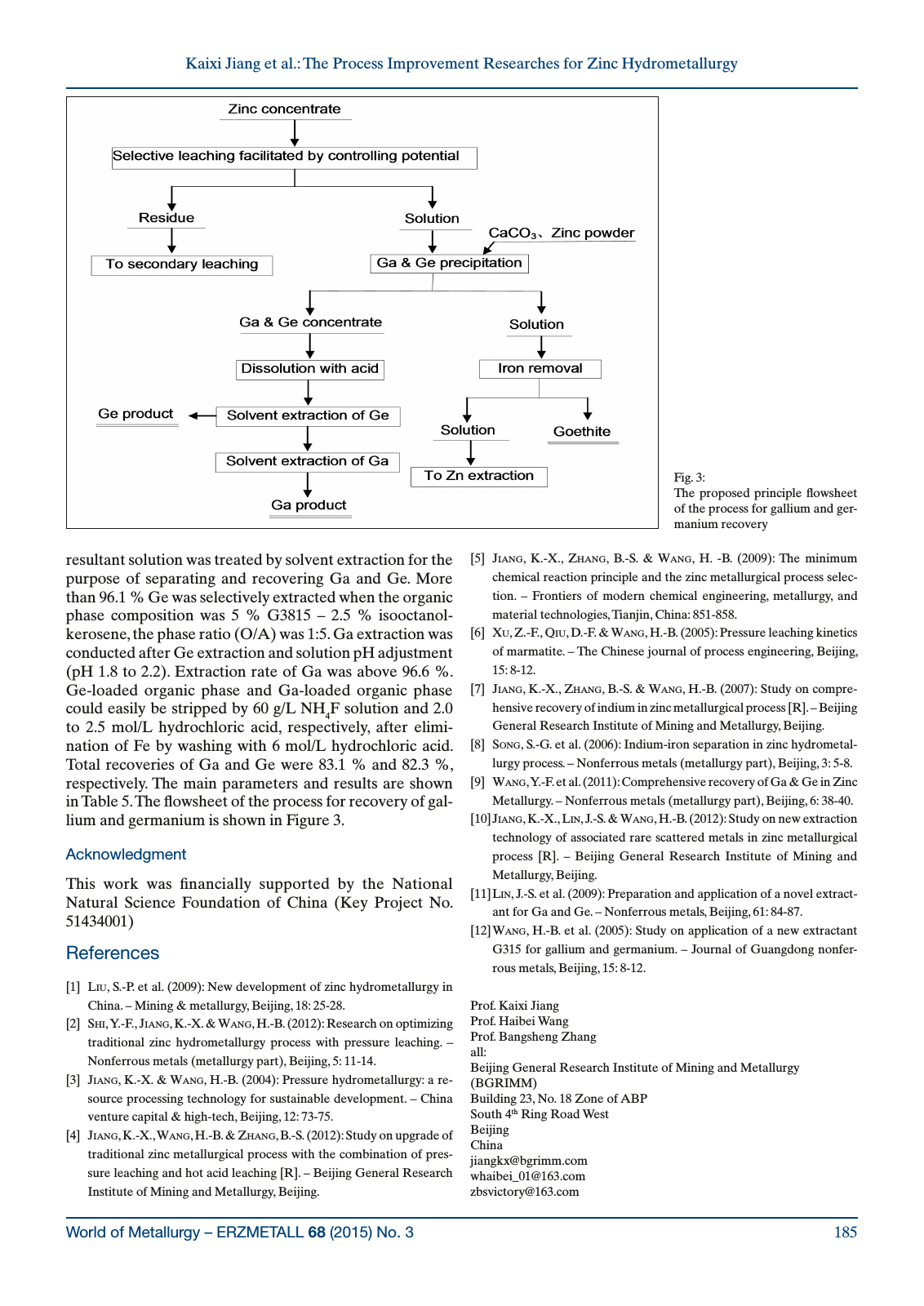

World of Metallurgy ERZMETALL 68 2015 No 3 185 Kaixi Jiang et al The Process Improvement Researches for Zinc Hydrometallurgy resultant solution was treated by solvent extraction for the purpose of separating and recovering Ga and Ge More than 96 1 Ge was selectively extracted when the organic phase composition was 5 G3815 2 5 isooctanol kerosene the phase ratio O A was 1 5 Ga extraction was conducted after Ge extraction and solution pH adjustment pH 1 8 to 2 2 Extraction rate of Ga was above 96 6 Ge loaded organic phase and Ga loaded organic phase could easily be stripped by 60 g L NH4F solution and 2 0 to 2 5 mol L hydrochloric acid respectively after elimi nation of Fe by washing with 6 mol L hydrochloric acid Total recoveries of Ga and Ge were 83 1 and 82 3 respectively The main parameters and results are shown in Table 5 The flowsheet of the process for recovery of gal lium and germanium is shown in Figure 3 Acknowledgment This work was financially supported by the National Natural Science Foundation of China Key Project No 51434001 References 1 Liu S P et al 2009 New development of zinc hydrometallurgy in China Mining metallurgy Beijing 18 25 28 2 Shi Y F Jiang K X Wang H B 2012 Research on optimizing traditional zinc hydrometallurgy process with pressure leaching Nonferrous metals metallurgy part Beijing 5 11 14 3 Jiang K X Wang H B 2004 Pressure hydrometallurgy a re source processing technology for sustainable development China venture capital high tech Beijing 12 73 75 4 Jiang K X Wang H B Zhang B S 2012 Study on upgrade of traditional zinc metallurgical process with the combination of pres sure leaching and hot acid leaching R Beijing General Research Institute of Mining and Metallurgy Beijing 5 Jiang K X Zhang B S Wang H B 2009 The minimum chemical reaction principle and the zinc metallurgical process selec tion Frontiers of modern chemical engineering metallurgy and material technologies Tianjin China 851 858 6 Xu Z F Qiu D F Wang H B 2005 Pressure leaching kinetics of marmatite The Chinese journal of process engineering Beijing 15 8 12 7 Jiang K X Zhang B S Wang H B 2007 Study on compre hensive recovery of indium in zinc metallurgical process R Beijing General Research Institute of Mining and Metallurgy Beijing 8 Song S G et al 2006 Indium iron separation in zinc hydrometal lurgy process Nonferrous metals metallurgy part Beijing 3 5 8 9 Wang Y F et al 2011 Comprehensive recovery of Ga Ge in Zinc Metallurgy Nonferrous metals metallurgy part Beijing 6 38 40 10 Jiang K X Lin J S Wang H B 2012 Study on new extraction technology of associated rare scattered metals in zinc metallurgical process R Beijing General Research Institute of Mining and Metallurgy Beijing 11 Lin J S et al 2009 Preparation and application of a novel extract ant for Ga and Ge Nonferrous metals Beijing 61 84 87 12 Wang H B et al 2005 Study on application of a new extractant G315 for gallium and germanium Journal of Guangdong nonfer rous metals Beijing 15 8 12 Fig 3 The proposed principle flowsheet of the process for gallium and ger manium recovery Prof Kaixi Jiang Prof Haibei Wang Prof Bangsheng Zhang all Beijing General Research Institute of Mining and Metallurgy BGRIMM Building 23 No 18 Zone of ABP South 4th Ring Road West Beijing China jiangkx bgrimm com whaibei 01 163 com zbsvictory 163 com

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.